Build a stronger, safer, and significantly more energy-efficient home.

Styrene-free for your family’s health & safety.

Thermal Efficiency

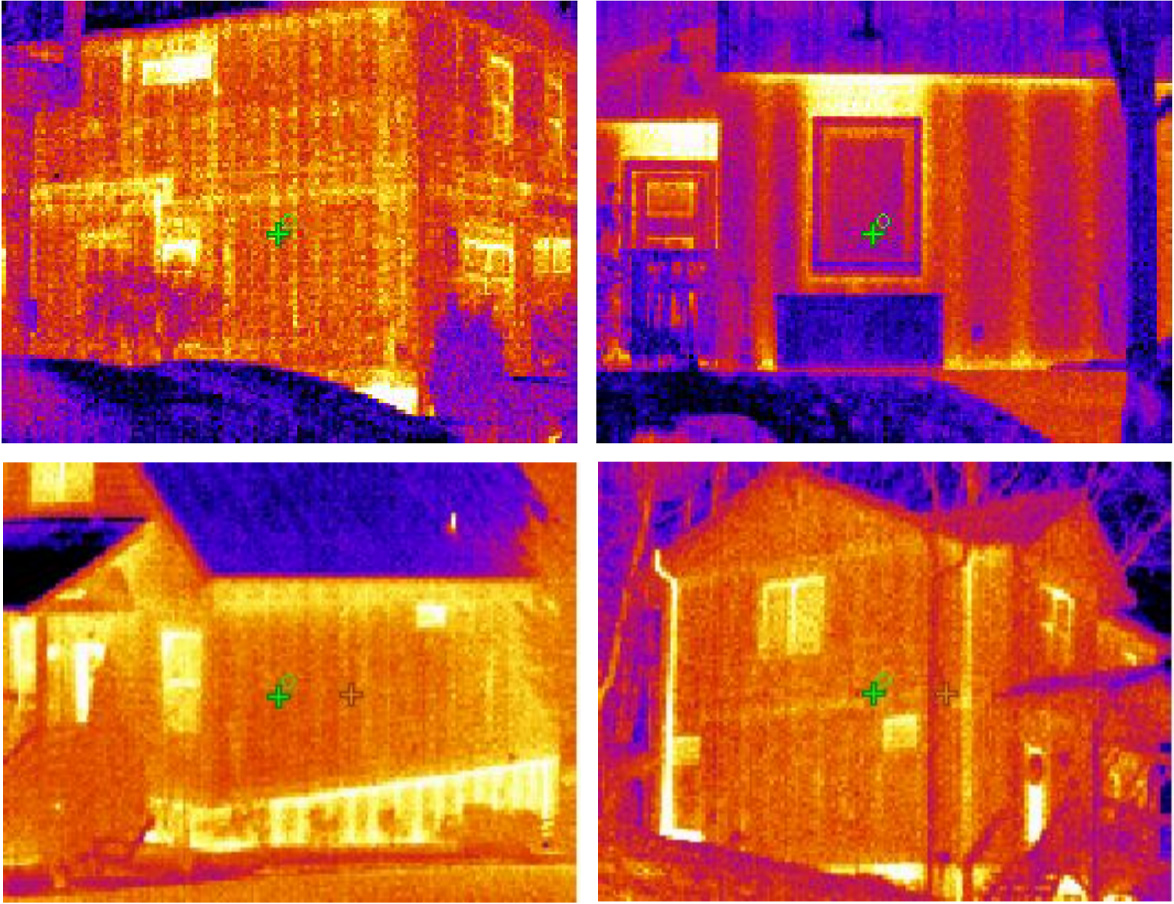

Pictures don’t lie. These thermal images tell the real story.

THESE ARE “GREEN-BUILT” 2×6 STUD FRAMED

HOMES WITH HIGH QUALITY INSULATION.

THERMAL IMAGING SHOWS THE MASSIVE ENERGY LOSS THROUGH THE STUD FRAMING

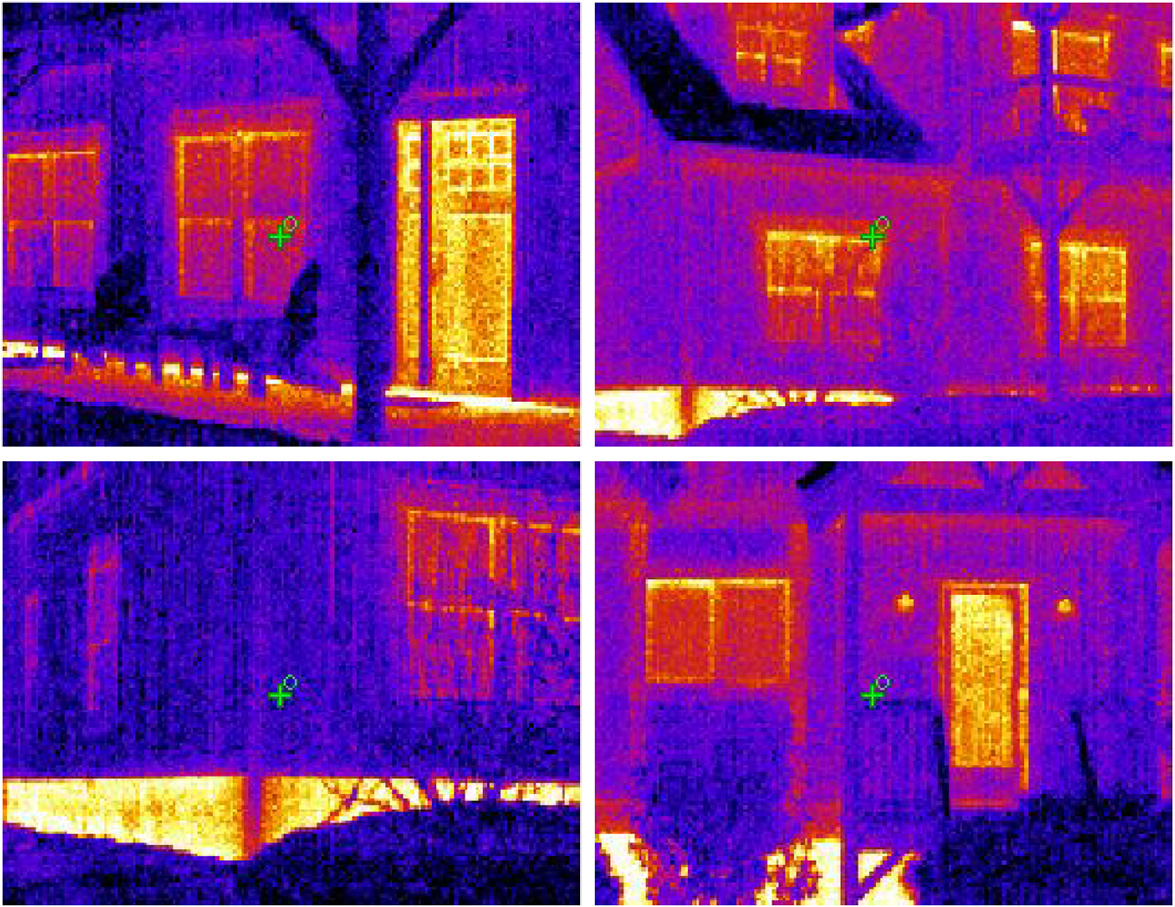

THESE HOMES ARE MADE WITH ECO-PANELS FOR ABOUT THE SAME PRICE AS THE STUD FRAMED HOMES.

THERMAL IMAGING SHOWS THE ENERGY LOSS IS PRIMARILY AT WINDOWS & DOORS, NOT THROUGH THE WALL SYSTEMS.

THERMAL EFFICIENCY

PICTURES DON’T LIE. THESE THERMAL IMAGES TELL THE REAL STORY.

THESE ARE “GREEN-BUILT” 2×6 STUD FRAMED HOMES WITH HIGH-QUALITY INSULATION. THERMAL IMAGING SHOWS THE MASSIVE ENERGY LOSS THROUGH THE STUD FRAMING

THESE HOMES ARE MADE WITH ECO-PANELS FOR ABOUT THE SAME PRICE AS THE STUD FRAMED HOMES. THERMAL IMAGING SHOWS THE ENERGY LOSS IS PRIMARILY AT WINDOWS & DOORS, NOT THROUGH THE WALL SYSTEMS.

Stronger. Safer. Faster.

At Eco-Panels, we help our clients build the strongest and most energy-efficient structures on the planet. Our building panels have been used for projects ranging from affordable housing to high-end custom homes and multi-family or commercial projects. Our product is so easy to use that many of our clients are using Eco-Panels to build their own home without previous construction knowledge – and these homes are performing much better than professionally built stud framed homes. Eco-Panels combines the framing and insulation process into one, easy step that makes your structure stronger, safer and considerably more energy efficient than a stud framed home.

Key Technology Components

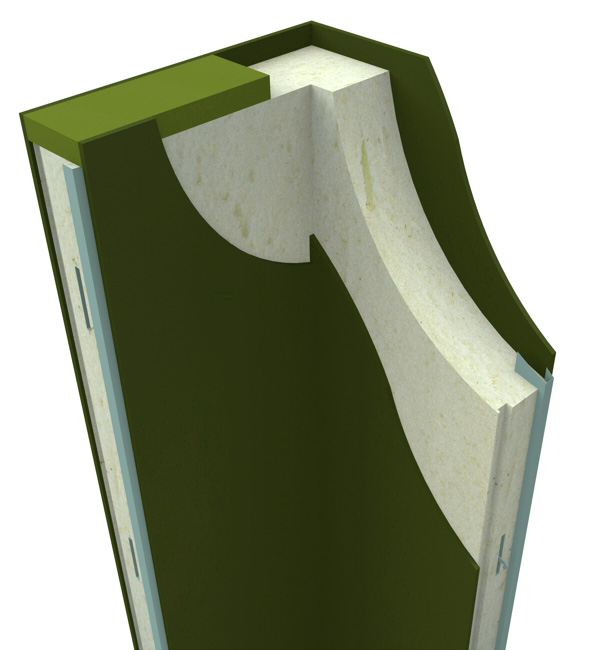

Single Piece Corner Panel

Eco-Panels unique and patented single piece corner building panel allows us to create an exterior having a wrap of continuous insulation – and that’s why we are creating the most efficiently insulated building envelopes on the market. It can be quite difficult to bring together two wall systems in the field and make them plumb and square. And it is then impossible to insulate at the corner continuously because you have vertical framing members helping to hold the two walls together. Our single piece corner panel eliminates the need for this framing at the corner and helps you to create a significantly stronger and more energy efficient building envelope. This also reduces the skill level required to build a stronger and much more energy efficient structure.

Integrated Cam-Locks

Most people are familiar with assembling furniture like from Ikea® that has nice embedded connecting systems. Eco-Panels has taken this one step further and has patented embedded connectors in a structural insulated wall panel. Saving time and money – most of our panel-to-panel connections use our cam-lock system – you simply stand on the interior floor platform and using a simple hex wrench lock the panels together. Typical spacing has our embedded cam-locks along the panel edge at every two feet. There is typically no need for scaffolding on the exterior to come back and nail panels together on the outside. This again reduces the labor and the materials required to create a stronger and more energy efficient wall system.

Flame Retardant and Organic-Based Foam Core

We’ve never seen anyone else take a less than one-inch thick piece of insulation on their upturned palm and hold a 3,600° F torch on it for long periods of time like we can (please do not try this with your own insulation!). Our custom blend of closed cell polyurethane foam core is without peer for its structural and adhesive strength, thermal insulating ability and it is free of any formaldehyde, styrenes or VOCs, and rated with an ozone depleting potential (ODP) of zero and a global warming potential (GWP) of less than one. While most SIPs on the market use a urethane adhesive to bond the foam core to the siding materials, our injected foam itself is the only adhesive that bonds together all components of our building panels with a force of almost 50 lbs per square inch. That’s around 14,000 pounds of bonding force for every panel square foot! By comparison a typical stud frame wall system has only one hundred to two hundred pounds of bonding force per square foot with nails and sheathing. With our panels having a bonding force this strong, significantly fewer fasteners are needed to build a very strong home or structure.

What Real People Are Saying About Eco-Panels

Recent Articles

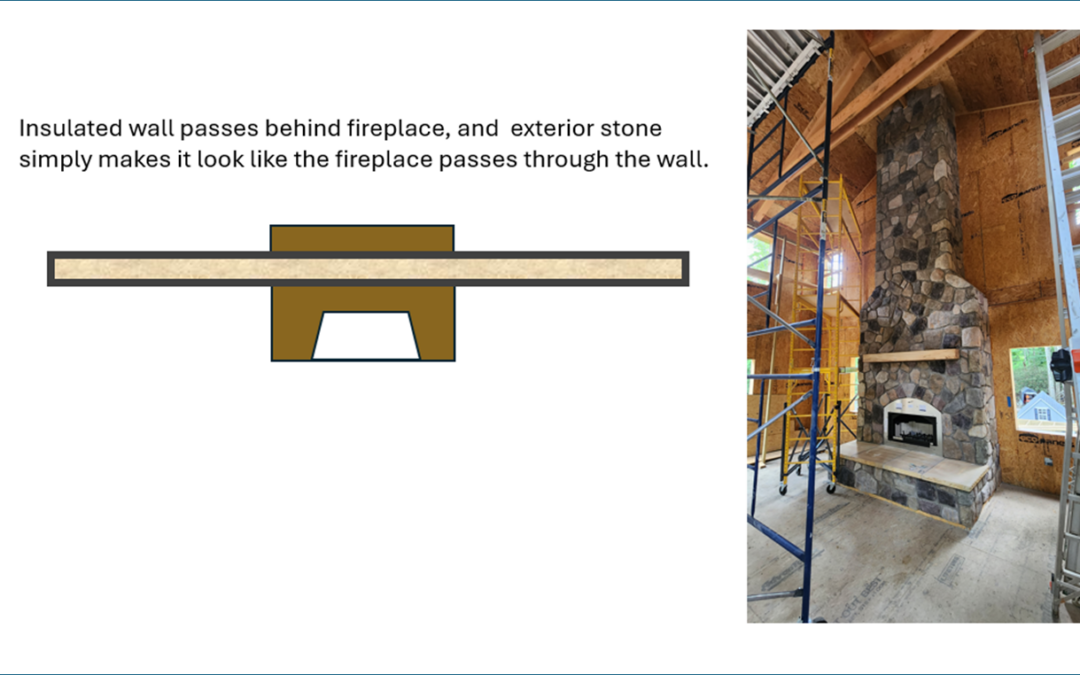

Energy Efficiency plus Beauty in Fireplaces

The stones and mortar of fireplaces are poor thermal insulators. Homebuilders can build insulated fireplaces by running Eco-Panels wall panels through the fireplace… building the fireplace on both sides of the wall panels. Observers think that the wall ends at the fireplace, but it goes through and insulates from heat and cold outside.

Recent Conversation with Prospective Client Relating to Advice For a Better Home

Every house is unique, and our panels and support are customized for each customer. Here’s a recent conversation with a DIY builder in Vermont, discussing how our panels can work best for his home.

The Importance of Indoor Air Quality

At Eco-Panels we try to help guide people through the process of building a very tight & energy efficient home – but indoor air quality is CRITICAL!!! Ventilation and filtration are key…

Highly Efficient Greenhouses

Do you ever find yourself wondering if food is important? Do you think...

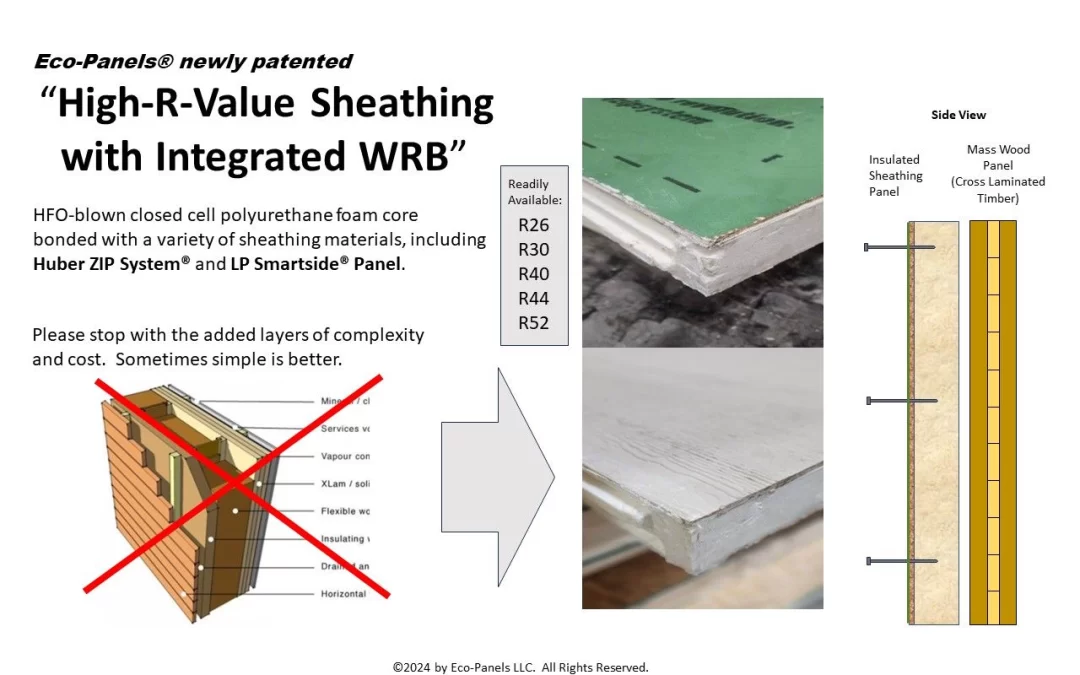

High-Insulation Value Sheathing with Integrated WRB

As Eco-Panels has ventured into the Mass Timber Market - Cross Laminated...