If you have made it to this page then you are certainly on the right track. Insulated structural panels of most types are superior in many ways to traditional stick-built methods. Here we’ll try to tell you why we believe Eco-Panels produces a superior product to traditional SIPs.

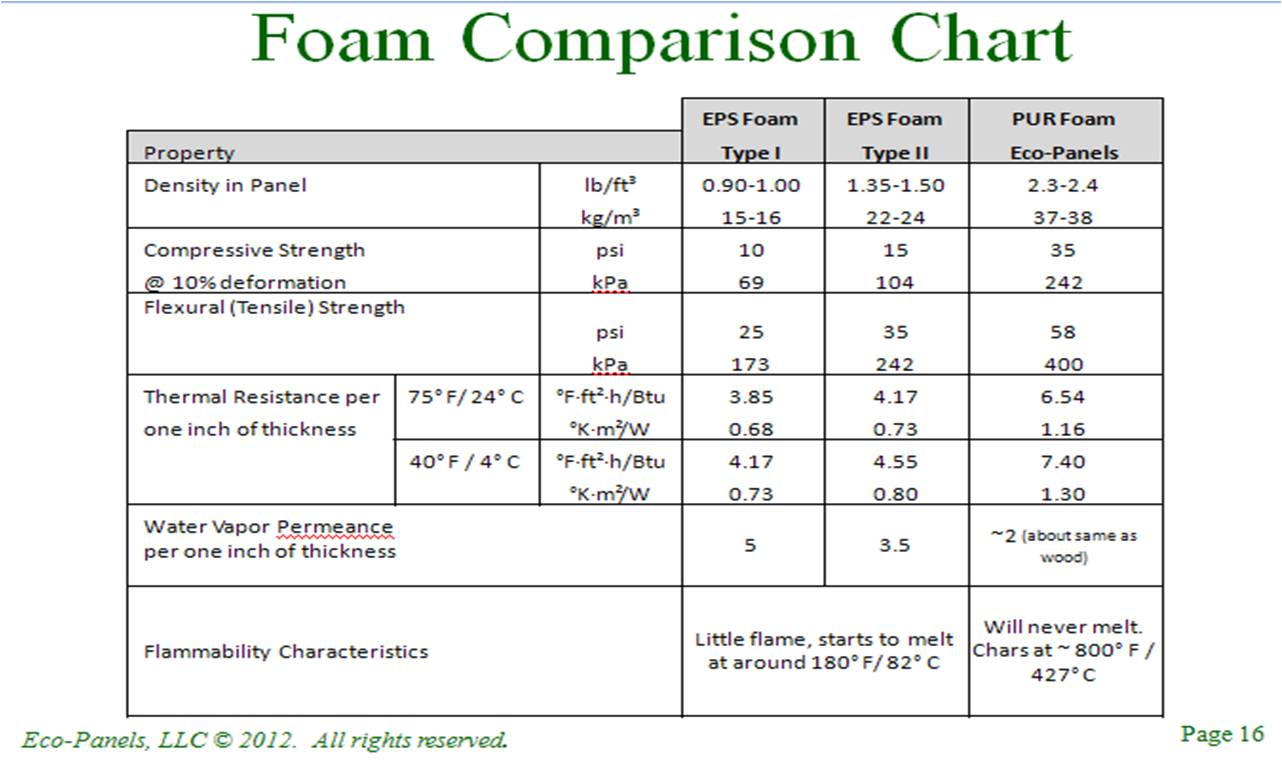

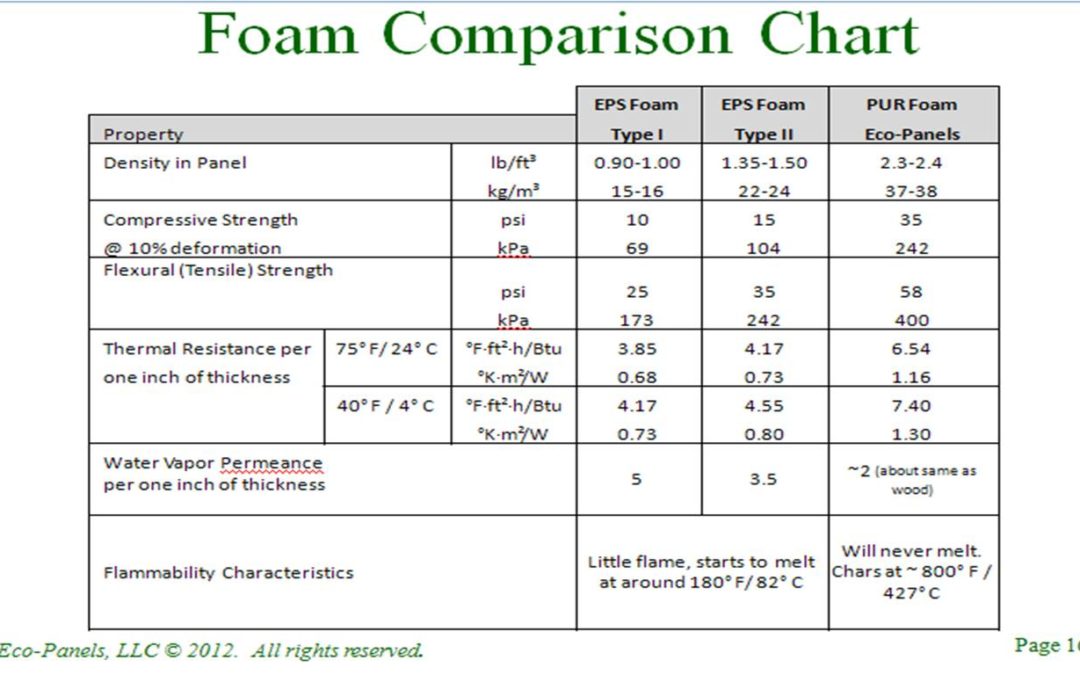

Lets face it, most of the time EPS panels are cheaper up-front than our panels – no doubt about it – but there will be often significantly more labor and product waste associated with EPS panels. We’ve seen their cost go anywhere from about 95% of our price to down around 50% of our price. Approximately 90%-95% of the United States SIP market uses EPS (expanded polystyrene) as an insulating foam core – and while some people simply refer to this product as Styrofoam® (it certainly looks like what we call a “styrofoam cup”), Styrofoam is simply a brand name for a single manufacturer of expanded polystyrene. EPS as building insulation evolved over the years from the construction industry and its stated R value appears to range from 3.5 to 4.0/inch based on density and manufacturer’s claims – not too different from fiberglass or cellulose insulation.  MAKE SURE YOU ASK WHAT DENSITY EPS FOAM THE MANUFACTURER WILL PROVIDE. It is often not easy finding this information unless you ask. The lower the density the weaker and less insulative per inch the product. EPS foam in panels typically starts around 0.9 to 1.0 lb/cuft density, sometimes goes to 1.5 lb density, and we have rarely heard it going to 2.0 lb density in the EPS SIPs market (be careful, on a quick glance it can all look the same). This product is inexpensive and in thick layers does a fine job of insulating a structure. SIPs made with EPS material, because the sidings have to stand far apart to achieve high R values, are quite strong and do a fine job of providing structural strength to a building. The additional wall thicknesses, however, will reduce interior square footage (for a given size envelope) and may cause problems when ordering window and door casings.

MAKE SURE YOU ASK WHAT DENSITY EPS FOAM THE MANUFACTURER WILL PROVIDE. It is often not easy finding this information unless you ask. The lower the density the weaker and less insulative per inch the product. EPS foam in panels typically starts around 0.9 to 1.0 lb/cuft density, sometimes goes to 1.5 lb density, and we have rarely heard it going to 2.0 lb density in the EPS SIPs market (be careful, on a quick glance it can all look the same). This product is inexpensive and in thick layers does a fine job of insulating a structure. SIPs made with EPS material, because the sidings have to stand far apart to achieve high R values, are quite strong and do a fine job of providing structural strength to a building. The additional wall thicknesses, however, will reduce interior square footage (for a given size envelope) and may cause problems when ordering window and door casings.

Most EPS panels are not structurally rated themselves unless accompanied by spline material – most often wooden members – that assist in joining the panels together. This is because the EPS panel industry generally evolved out of the timberframe industry where blank panels were simply cut on the jobsite to be applied to a wooden timberframe (the wooden frame carried the structure of the building). Most often you have to supply this spline material yourself and finding straight 2x lumber these days and inserting into the edge voids to tie panels together can be challenging – windows, doors, top plates, panel splines, etc. Once installed – and regardless of the type of spline material all EPS panels require the installer to have to nail/screw along the panel edge on both sides of the wall – this additional lumber will provide a thermal wick to allow for the transfer of either cold or hot energy through the building envelope. Even some of the most advanced and small zero-energy homes (ZEH) can have over 30 square feet of thermal bridging of R3.5 (the R value of the 2×4 stud in the wall) material from these spline materials. If the EPS company is not simply selling “blanks” (plain panels to be cut on site), the pre-framing of windows and doors is cost-plus option and I would advise that you choose it – the cutting of panels on-site, if not done properly, can lead to voids or other quality related issues that can cause problems for the entire life of the structure.

Perhaps the biggest concern with EPS or Polystyrene panels is health and safety. In June of 2011 the National Institutes of Health released its 12th annual Report on Carcinogens, listing Styrene right along with Formaldehyde. The FAQs especially note that people can be exposed to styrenes from things like cigarettes and building insulation. This report came out after fast food restaurants started banning Polystyrene containers due to concerns about the migration of the Styrene into food. The blowing agent Pentane is a VOC while it is mostly consumed in the manufacturing process, some studies have shown approximately 30% of the blowing agent remains with the panels. And green building experts have long noted other health concerns with Polystyrene insulation, as noted here by Environmental Building News. Yes, the Chemical Industry disagrees with the reports findings, but of course they would. The Natural Resources Defense Council has a good take on their “Swift Boating” of the science through extensive (and unfair) lobbying practices here. But remember, if you are building an air-tight home that you will spend a significant portion of your life in, why take the chance? My wife worked like crazy to find baby bottles for our children that did not contain the chemical compound BPA, and I know she would be equally concerned about living in an air-tight envelope of potentially toxic material.

Structure can be another great concern. Polystyrene foam typically starts to deform or melt at around 180°-200° deg F. Just about everyone can relate to tossing a foam coffee cup into the fire – it simply disappears. Many manufacturers claim that their EPS foam does not burn and they have flame retardants in it and that’s great, but I’ve never seen them claim that their foam does not melt or vaporize. I have heard building scientists working for US Dept of Energy at Oak Ridge National Labs note that they have seen EPS roof panels delaminate in the heat of the sun (of course those may have been metal sided panels – it was not clear in his speech) and we heard of an instance in Colorado where the contractor installed clear polyethylene plastic over the roof panels prior to a stormy weekend, and when they returned the “greenhouse effect” caused them to delaminate due to the very top layer of EPS foam melting.

If you consider the panel as an I-beam, when you remove the center web of foam (or it simply disappears due to the heat of a fire), you lose structure – the entire structure collapses. We are not concerned about people getting out of a house – you should have plenty of time for that I think – but what about the firemen coming 15 minutes later? Remember these panels are holding up your roof and everything else over your head. EPIC, or Engineered Panels in Construction, a UK trade organization, notes that over 95% of the structural insulated building panels used in the UK have a polyurethane – and not EPS – foam core, and for good reason. Their 10 year study of fires in buildings notes:

“…it is particularly significant that polyurethane panels were involved in 3.4% of the total fires and these fires accounted for 3.1% of the financial loss to insurers. In stark contrast polystyrene panels were present in 12.8% of the total number of fires but these fires represented 26.8% of the total insurance loss. This data confirms that insurer losses in fires involving polystyrene are higher than with other types of insulated panel systems – confirming the link between polystyrene panels and higher insurance losses.”

See the link: http://www.epic.uk.com/fire_research.jsp

The foam in our panels have not been subject to similar health concerns and do not contain brominated flame retardants like EPS foam has. Because we are passionate about offering the best thermal envelope Eco-Panels uses only a polyurethane, or PUR, foam core. Whether defending against hot weather or cold our foam offers one of the best insulation “R” value per inch available. Initial R values are approximately 7 per inch and our 4.5” panels have an R value of 26 at 55 degrees Fahrenheit – EPS panels need about an 8 inch panel to reach the same value. And our 6.5” thick panel reaches R40. The Eco-Panels system actually evolved from the walk-in cooler/refrigeration industry – the folks who have been the best at controlling the thermal envelope for over 50 years. The polyurethane foam we use in our panels is the same foam mix used in many of the most advanced and efficient home refrigerators on the market today. To use an analogy of the soft-drink cooler you might purchase at the beach or for a picnic, ours is not the cheap white crumbly styrofoam-like cooler (the EPS panel), rather it is the nice strong Igloo®-like cooler – with a molded shape and lasting, dependable quality. Our foam does not off-gas (see FAQs for more information on this) and it does not contain CFCs, HCFCs, VOCs or formaldehydes that can be harmful to people and the environment. With respect to safety polyurethane foam is a thermoset material – it does not melt and under most conditions does not promote flame. Please see the page on “SIP Burn Test” for a demonstration of how our foam (and our competitors’) reacts to a blow torch. The strength of our foam, when coupled with even basic siding materials like OSB, has exceeded vertical compressive strength tests of over 50,000 lbs for a single 4’x8’, 4.5” wide panel!

To avoid the costly and often defect inducing practice of altering panels on site, windows, doors and electrical boxes/conduit are pre-framed or molded inside of our panels under factory conditions. To date we are using over 15 different siding materials on our panels ranging from simple OSB to various curtain-wall materials and even pre-finished siding materials such as LP Smartside® for the panelized or board & batten look. After windows and doors the corner of an exterior wall offers the greatest opportunity for thermal energy loss – our patented corners are molded at 90° or 135° in our factory and delivered to your site plumb and square – no more trying to make sides come together correctly with additional framing materials to wick thermal energy. To start erecting the walls simply start at the corner and start working around the perimeter using our cam-latch system and supplied sealant to quickly lock the panels together.

In summary we believe the Eco-Panels system is the most advanced panelized framing solution on the market today and far superior to traditional SIPs. Please take a few moments to review this website and please do not hesitate to contact us if you have any questions or concerns.

Recent Comments